We use rapid molding technology (such as 3D printing, CNC processing, laser cutting, etc.) to make a preliminary model of headlights. For sophisticated lamp shapes, high-precision 3D printing techniques such as SLA, SLS, or multi-sprinkler head deposition modeling (MJDM) may be required.

Order(MOQ) :

1 setsprocessing technic :

CNC plastic processingmaterial trademark :

ABS-SLASampling / production cycle :

3 Days / 7 daysProduct processing accuracy :

≧+/-0.001mmProduct processing process :

The cnc processing-full inspection-packaging-shipmentsize of product :

OEMsurface treatment process :

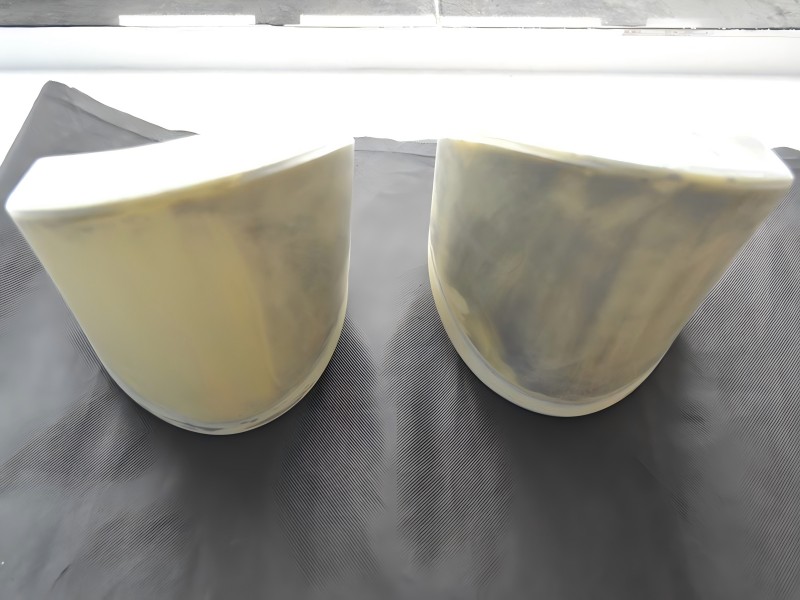

assembleOur car headlamp prototypes CNC machining services offers precision and efficiency in creating rapid prototypes for automotive lamps. Utilizing advanced CNC technology, we produce highly accurate and detailed lamp prototypes, ensuring they meet the stringent requirements of the automotive industry. Our service is ideal for manufacturers looking to expedite their product development cycle, providing quick turnaround times without compromising on quality. Whether it's for headlamps, taillights, or other lighting components, our CNC machining ensures that each prototype reflects the exact design specifications, allowing for thorough testing and validation before mass production.

| Place of Origin | Shenzhen, China |

| Type | Laser Machining, Milling, Other Machining Services, Turning, Rapid Prototyping |

| Micro Machining or Not | Micro Machining |

| Brand Name | JCR CNC Models |

| Material | ABS, PMMA, PC, PA, aluminum, S304, Brass,etc |

| Type | CNC machining |

| Process | 3 axis, 4 axis, 5axis |

| Application | Motor, Auto, Consumer electronics |

| Size | Customized |

| Tolerance | 0.01mm - +/-0.05mm |

Case introduction

Lamp manual processing usually refers to the prototype model made in the development and design stage of automobile lamps. Hand plate (or sample, sample) is the sample used during product development to verify the design concept, functional realization, appearance effect, and various tests. The processing process of the lamp hand pads may include the following steps:

Design: Use CAD software to design the headlights to ensure that they meet the functional requirements, aesthetics and the matching degree with the whole vehicle.

Material selection: According to the type of hand plate (such as appearance model, structural model or functional model), choose the appropriate materials, such as ABS, PC, acrylic (PMMA), nylon, or metal materials such as aluminum alloy.

Rapid molding: using rapid molding technology (such as 3D printing, CNC processing, laser cutting, etc.) to make a preliminary model of headlights. For sophisticated lamp shapes, high-precision 3D printing techniques such as SLA, SLS, or multi-sprinkler head deposition modeling (MJDM) may be required.

Post-processing: Rapid formed models usually require polishing, polishing, painting and other post-processing work to obtain a more accurate and aesthetic appearance. In some cases, transparent or translucent processing may also be required to simulate the lens effect of real headlights.

Assembly and testing: Install the lamp hand to the vehicle for fitness checks and functional testing. These tests may include optical performance tests such as the range of light exposure, brightness, and color temperature.

Evaluation and iteration: evaluate the hand board according to the test results. If any problem or deficiency is found, the design should be modified and the hand board should be rebuilt. This process may be repeated many times until the product reaches a satisfactory level.

Final confirmation: When the lamp hand plate passes all necessary tests and meets the design requirements, it can enter the next production preparation stage, such as mold manufacturing preparation.

Lamp hand plate processing is a key link that helps designers and engineers find potential problems before actual production and ensure the quality and performance of the final product.

Why Choose Us?

The group was established in 2013 and has now become an international medical group integrating R&D, manufacturing and sales, with multiple subsidiaries and overseas branches. In the past few years, we have obtained FDA, CE, ISO13485, ISO9001 and other international certifications. In 2020, we achieved sales revenue of more than US$50 million. The existing factory area is approximately 33,000 square meters; a factory covering an area of 68,000 square meters will begin operations in 2022. We focus on product quality and have strict quality control. Products are mainly positioned in high-end medical markets, such as the United States, the United Kingdom, Canada, Western Europe, Australia, etc. We mainly cooperate with major medical groups in North America and Western Europe to develop long-term friendly cooperation.

We have the most advanced automated production lines, a professional team, and a flexible strategic management system. We will provide the most professional products and the most sincere services to customers around the world. We will continue to adopt a globalization strategy, improve service quality, expand brand reputation, and become a competitive international enterprise.

FAQ

Q1: What information do I need to provide for a quotation?

A1: Please share your 2D/3D/Assembly drawings along with detailed requirements such as materials, tolerances, and any specific instructions. The more comprehensive your information, the more accurate our quotation will be.

Q2: How quickly can I receive a quote?

A2: We typically respond with a quote within 24 hours of receiving your inquiry. If your request is urgent, please call us or highlight it in your email so we can prioritize your inquiry.

Q3: What is the preferred format for 3D files?

A3: We prefer STP files, but STEP and STL formats are also accepted.

Q4: How long does it take to get a sample?

A4: The time frame depends on your specific requirements and quantity. Generally, samples are prepared within 3-7 days.

Q5: Is it safe to send my drawings to you?

A5: Yes, your information is secure with us. We do not share it with third parties without your permission, and we are happy to sign an NDA if required.

Q6: How can I be assured of the product quality before shipment?

A6: Our professional QC team inspects each product before shipment. You are welcome to visit our factory, request a third-party inspection, or ask us for production process videos.

Q7: What payment methods do you accept?

A7: We accept T/T, Alipay, PayPal, Western Union, and L/C. Please choose the method that is most convenient for you.

Q8: What are the available shipping options?

A8:By sea to your nearest port

By air to your nearest airport

By express (DHL, UPS, FEDEX, TNT, EMS) to your door

Q9: What should I do if I receive a defective prototype?

A9: Please send us the inspection report along with photos highlighting the defects. We will review our inspection records and discuss the next steps with you. If the defect is due to our quality or shipping issues, we will replace the defective prototypes within 10 days. If you return the prototype to us, we will issue a refund.

Q10: Special considerations regarding prototype quality?

A10: Prototypes differ from standard products, often involving fast delivery and urgent processing. Some details may not perfectly match the drawings, and adjustments may be needed during assembly. Certain designs may be challenging to achieve through machining, leading to a prototype that functions differently than the final product. This is common in prototyping and not considered a quality issue. Our engineers will discuss any such concerns with you during the data analysis stage before you place your order.

Our hours

Mon 11/21 - Wed 11/23: 9 AM - 8 PM

Thu 11/24: closed - Happy Thanksgiving!

Fri 11/25: 8 AM - 10 PM

Sat 11/26 - Sun 11/27: 10 AM - 9 PM

(all hours are Eastern Time)