ISO 9001:2015 certified prototype supplier to ensure that your project meets strict quality specifications.

ISO 9001:2015 certified prototype supplier to ensure that your project meets strict quality specifications.

One-to-one support service by a technical team, quick response within a few hours.

One-to-one support service by a technical team, quick response within a few hours.

Most competitive prices in the market, 30% lower than Europe and America.

Most competitive prices in the market, 30% lower than Europe and America.

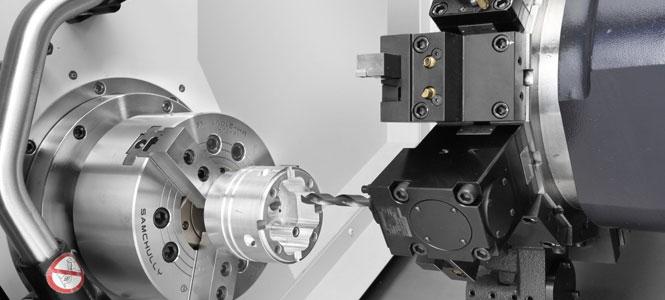

Comprehensive capabilities include in-house machining and integration of manufacturing resources across China.

Comprehensive capabilities include in-house machining and integration of manufacturing resources across China.

An experienced team of engineers and flexible production methods mean faster manufacturing and shorter lead times.

An experienced team of engineers and flexible production methods mean faster manufacturing and shorter lead times.

Dedicated Employees

Countries Served

Satisfied Customers

Projects Delivered Per Month

Directly upload your file or send your project message through the quote page. All files are under NDA supported.

Directly upload your file or send your project message through the quote page. All files are under NDA supported.

Directly upload your file or send your project message through the quote page. All files are under NDA supported.

Directly upload your file or send your project message through the quote page. All files are under NDA supported.

September 06, 2024

September 06, 2024

Details

Details

JCR CNC Models has been engaged in precision parts for more than 10 years. From the initial optical communication parts processing to the current military parts processing, the difficulty coefficient is getting bigger and bigger, so how to design the process allowance of complex precision parts processing? For a brief share: In the process of precision machining, we change the geometry of the parts to process the cutting size, which I call as the processing allowance. The size of the processing allowance has a great impact on the processing speed, quality and processing cost. If the processing allowance is too large, it will not only increase the processing labor amount, reduce the production efficiency, but also increase the consumption of materials, tools and power, and increase the processing cost. If the processing allowance is too small, it can not eliminate various surface defects and the error of the previous process, nor can it compensate for the installation error of the workpiece in the process of processing, which is easy to make the workpiece scrapped. Cutting margin is commonly used in our processing by the following methods: 1. Check the table According to the processing allowance data provided by the relevant processing manual, combined with the actual production situation of our factory, the processing allowance is determined after correction, which is a common method in large processing plants.2. The empirical estimation method Determine the processing allowance according to the processing experience of the processing technicians. What is the main basis that processing process personnel determines processing allowance standard? (1) The minimum processing allowance is used to shorten the processing time and reduce the workpiece manufacturing cost. (2) There should be sufficient processing allowance, especially for the final processing procedure. The machining allowance shall ensure the surface roughness, size, shape and position accuracy specified in the machining drawings (3) sufficient machining allowance to eliminate the workpiece deformation caused by heat treatment. (4) When processing allowance, the possible changes of processing methods, processing equipment and workpieces in the processing process should be considered.(5) When formulating the processing allowance, the size, shape and other factors of the work piece should be considered.3. Analysis and calculation method According to the theoretical formula and related experimental data, the factors affecting the processing allowance are analyzed and calculated to determine the processing allowance. What is the calculation formula of the processing allowance? (1) The minimum allowance is calculated as follows: Surface treatment: zbmin = aamin abmax Cylinder processing: 2 zbmin = Damin dbmax Internal surface treatment: zbmin =abmin aamax Inner hole processing: 2zbmin =dbmin damax Note: zbmin (minimum margin on one side in this process), 22 bmin (minimum margin of double-sided diameter in this process), aamin, amin, aamax, damaX (minimum and maximum limit size of previous process), abmin, dbmin, abmax, dbmax (minimum and maximum limit size of this process (after processing)) (2) The calculation formula of the maximum tax exemption is as follows Zbmax =Zbmin + Ta + Tb 2Zbmax=2Zbmin +Tda +Tdb Note: TA, TDA (dimensional and diameter tolerances for the previous process), TB, TDB (dimensional and diameter tolerances for this process) (3) Calculation formula of the basic tolerance of internal and external surface processing: Unilateral allowance: ZB basic =zbmin + ta Column allowance: 2 ZB base = 2 zbmin + TDO Inner hole allowance: 2 ZB base =2zbmin + TDA The above is the design method of the processing process of complex precision parts, which is often used by the personnel engaged in engineering design, or the programming technicians will also refer to it.

September 06, 2024

September 06, 2024

Details

Details

Different precision machining enterprises have their own good industries and fields, electronic equipment industry also has a lot of precision parts need precision machining to complete, suitable for cnc processing and lathe processing, stamping forming, etc. Through keyword search, electronic parts processing this kind of keywords, can search to a lot of precision machinery processing enterprises, electronic parts processing is precision machinery processing enterprises favored different industries, product quality requirements and quantity are not the same, precision parts processing in electronic equipment industry generally have a certain batch, this is one of the reasons favored by precision machining enterprises, precision parts inside the electronic equipment industry level and military industry or medical industry, precision group is precision machinery processing enterprises so accepted, can meet the requirements of the precision processing. Electronic equipment industry precision parts is given priority to with copper, rarely special material material, so in parts of processing difficulty is relatively easy, in the lack of technicians today, a product change machine, can for a long time of processing, this is also a precision machinery processing enterprise love, so precision parts of electronic equipment industry is very suitable for precision machining enterprise industry. Sanwei Kaide Precision Industry focuses on medical precision parts processing, optical communication equipment parts processing and other industries for many years, but also serves the automation equipment industry customers, uav industry, electronic equipment industry, etc

August 06, 2024

August 06, 2024

Details

Details

Some people often ask whether stainless steel will rust, the answer is to rust, stainless steel in a specific environment, the surface will produce corrosion and rust, to prevent stainless steel rust passivation and anti-rust oil, so what is the difference between the two? The reason for stainless steel rust is because the surface of a very thin layer of rich Ming oxide film can protect up, But our daily complex processing process will to a large extent destroy this protective layer and leave iron powder on the surface of the product, Or the iron ions in the free state, And iron ion is one of the important causes of rapid rust, Also because of the harsh environment used by the parts, Stainless steel is much easier to rust, withal, Stainless steel is generally rust-resistant, Passivation is the use of the oxidizing substances in the passivation fluid, Generduce redox reactions with metal, Promote the formation of a very thin bell film on the metal surface, To protect the surface of stainless steel from corrosion, This process is considered as a chemical reaction, The resulting passivation film is dense, The whole is not easily destroyed. And rust oil is the use of oil film to close the metal surface of the air hole, to achieve the purpose of isolation and contact with oxygen, so as to effectively prevent stainless steel cow rust, is a kind of physical reaction worthy of the name, oil film is easier to proceed with the production, and be removed and destroyed, resulting in rust failure.

August 06, 2024

August 06, 2024

Details

Details

Our hours

Mon 11/21 - Wed 11/23: 9 AM - 8 PM

Thu 11/24: closed - Happy Thanksgiving!

Fri 11/25: 8 AM - 10 PM

Sat 11/26 - Sun 11/27: 10 AM - 9 PM

(all hours are Eastern Time)